VacFlow - non-mechanical sampler

Representative samples - no mechanical components

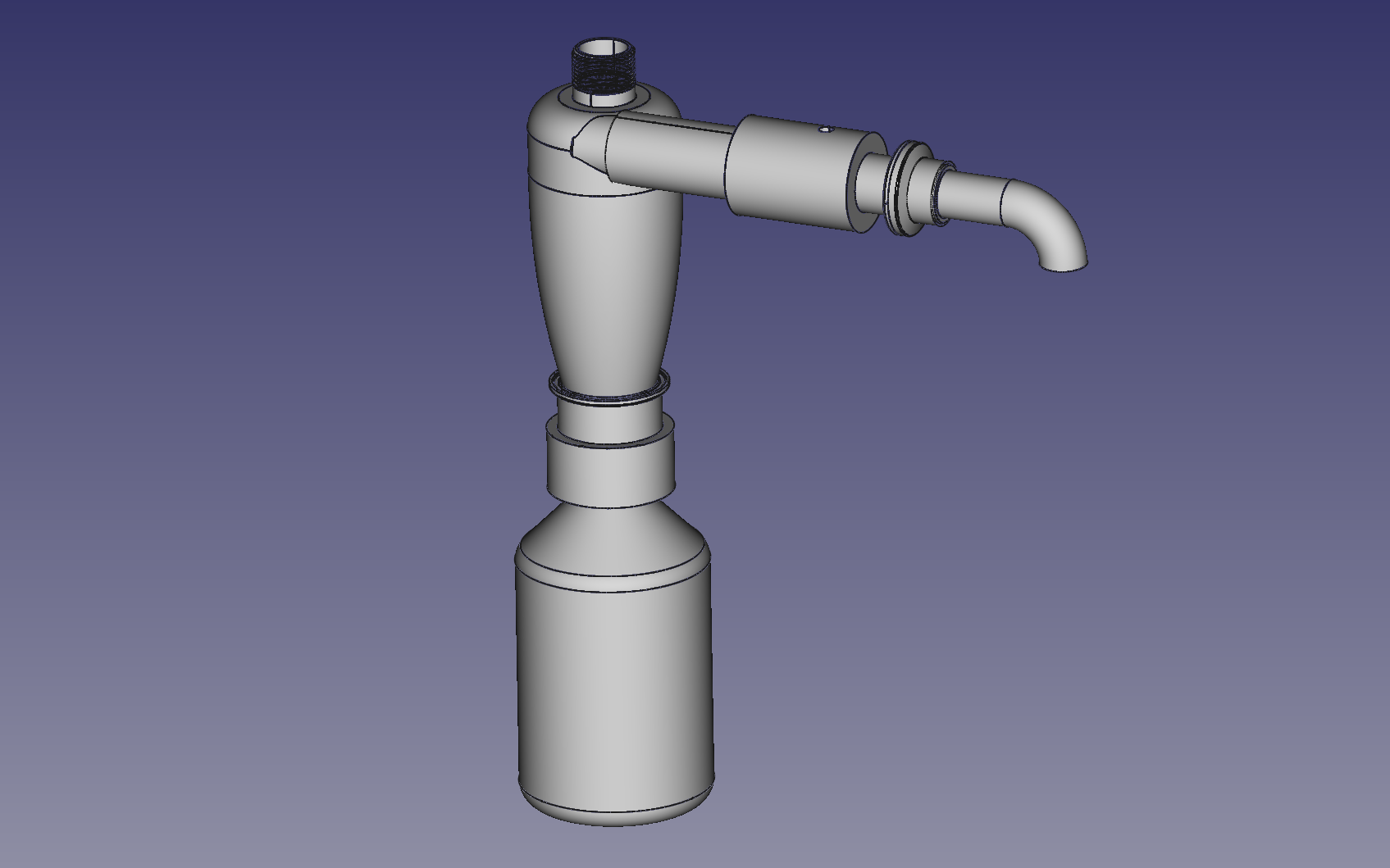

Jamming, clogging, blocking: From now on, these sampling problems should be a thing of the past - with the VacFlow. Because this bulk sampler has no mechanical components that could be affected by the bulk material and its particles.

The system can be used almost anywhere, in the downpipe, in the bin or silo, thanks to a number of clever options.

Actuation: Compressed air

Sample: ca 5ml per actuation (depending on bulk properties)

Material: Stainless steel 316, aluminium, POM (food grade)

inclusive bottle adaptor for Laboratory bottles with GL45 and weld boss DN32

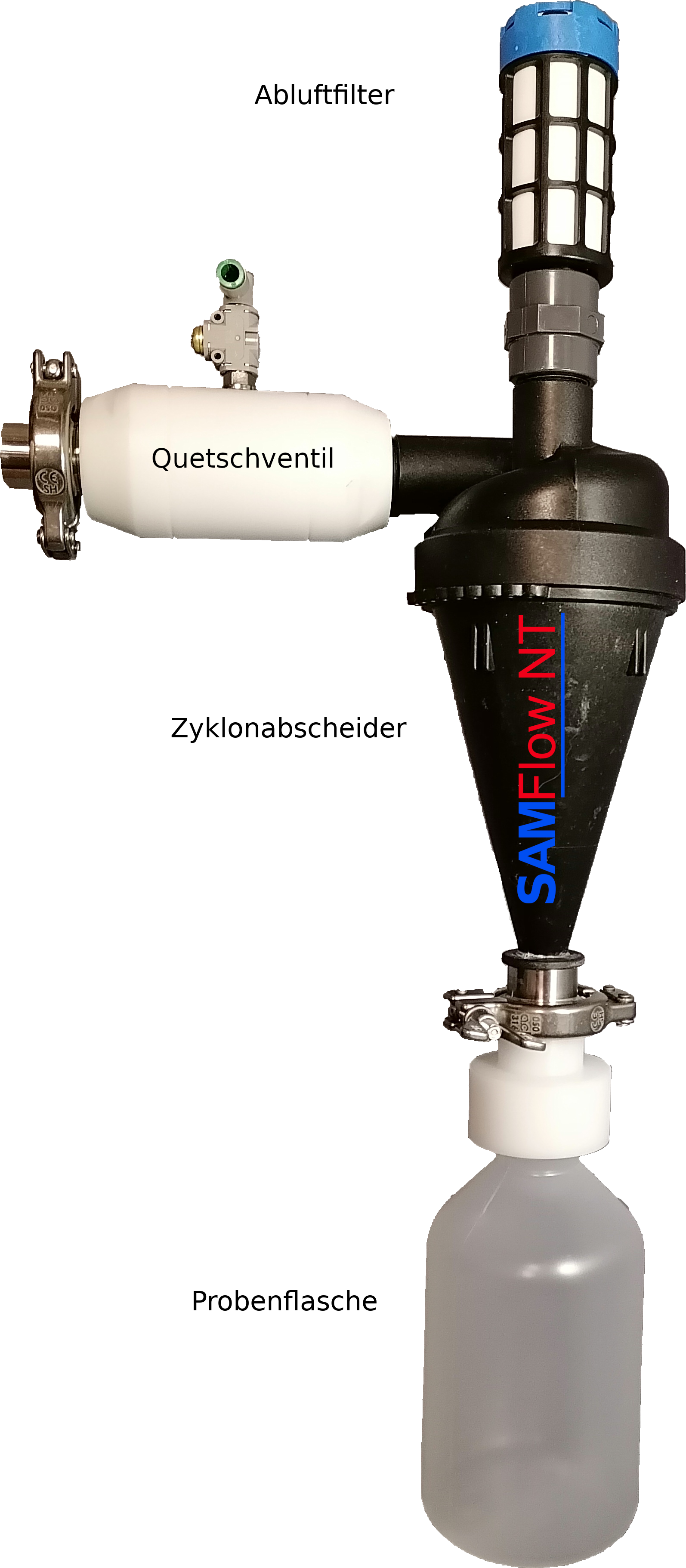

Innovation: SamFlow NT for pneumatic conveying

Representative samples from pneumatic conveying

The new SAMFlow NT is a further development of the proven SamFlow sampler. This device allows samples to be taken from pneumatic conveyor systems. A highly efficient cyclone separator made of PP is used. The sample is then collected in a 1-5 litre sample bottle.

Sampling is sensibly carried out at short intervals over the entire conveying process and can also be automated with the help of a pneumatically operating timer control.

Thanks to the use of triclamp connections, food-safe materials and optimised geometries, the sampler can be dismantled and cleaned in a short period of time. The assembly itself is done on a 1 inch triclamp, which is installed in the convey line.

Weblink: SamFlow NT

Sampler for plastic granules in octabins and big bags

For the first time representative samples in seconds!

The newly developed JETSAMPLER was used for the first time in a compounding machine. The company buys plastic regrind from all over Europe and processes it into so-called compounds. It is therefore extremely important that the raw materials intended for processing meet the required quality characteristics.

Sampling from containers such as octabins or big bags has always been a great challenge for quality managers and personnel in this company. If sampling took place, it was usually only from the surface or at specific points. As this was not a representative sample, it was not sufficient for the assessment of the total quantity.

The JETSAMPLER offered a remedy and the possibility of representative sampling. It takes a sample that corresponds to a core hole over the entire height of the container in a very short time and with minimal effort.

In a test, an octabin was filled in layers with different coloured plastic granules and a sample was taken from it with the help of the JETSAMPLER . The sample, taken in one step and collected in a bucket, contained all layers and colours in representative proportions. Although the octabin was filled to a height of 1.6 metres, the sampling process only took a few seconds.

Thanks to the two-meter-long aluminum lance, the JETSAMPLER can also penetrate to this depth and collect representative samples. In doing so, the instrument generates a circulating air stream that conveys the bulk sample and then transports it via a solids separator directly into the sample collection vessel. This can be removed and replaced very easily.

By using food safe materials and optimized geometries, the JETSAMPLER is virtually self-cleaning.

Weblink: GMP-Sampling